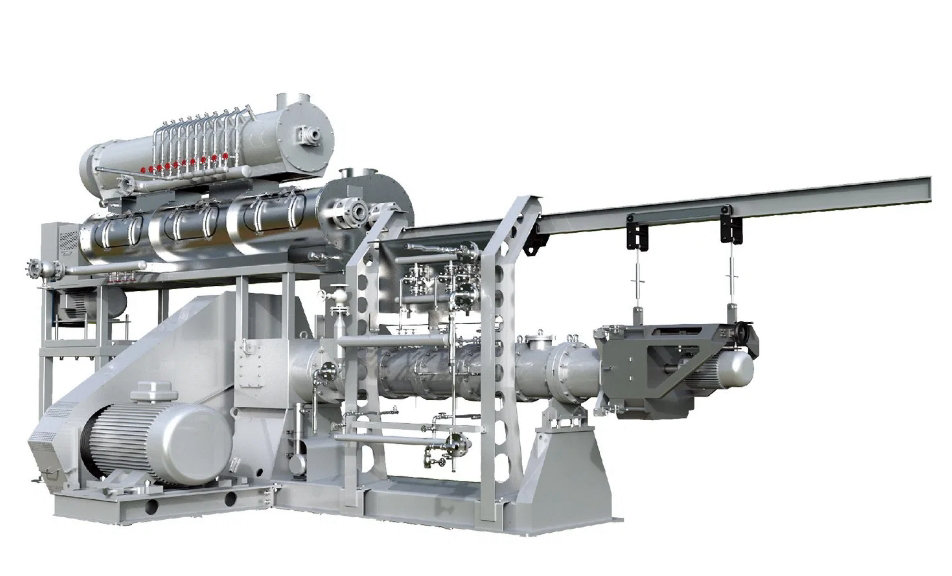

Puffing machine

Puffing machine

Main features

Technical reference

1. High lifespan gearbox; Wear resistant alloy screw liner: screw service life>; 22000 tons, with lining

Service life>50000 tons, gearbox free warranty of 30000 hours: integral forging expansion chamber: no leakage deformation:

Double layered jacket for expansion chamber, capable of heating or cooling

2. High precision gears, imported high-quality bearings and oil seals, advanced gearbox design and processing technology control

Manufacturing technology, equipped with torque limiters to ensure smooth, safe, and reliable transmission

3. Fully engaged, zero clearance twin-screw mechanism effectively controls shear force to ensure that all materials expand during puffing

The maturation time inside the cavity is consistent with the coefficient of particle expansion

4. The new type of fully wear-resistant alloy screw and bimetallic expansion cavity sleeve effectively reduce wear and ensure that the equipment operates at high temperatures

Long term stable operation under production capacity and high-quality conditions

5. Effectively allocate reasonable shear forces in different areas of the extrusion chamber while ensuring high quality

Effectively increase production

6. The discharge of the raw material device makes the extruded expanded material more aesthetically pleasing, and the output of the small hole diameter mold increases by 30%-

40%. The material shape is uniform and stable

7. The automatic control system simplifies operations and reduces manual labor intensity. Make all data traceable

Record and minimize the impact of operators on the quality of puffed products; Advanced Control Components in Europe

Ensure the stability of the control system

Service life>50000 tons, gearbox free warranty of 30000 hours: integral forging expansion chamber: no leakage deformation:

Double layered jacket for expansion chamber, capable of heating or cooling

2. High precision gears, imported high-quality bearings and oil seals, advanced gearbox design and processing technology control

Manufacturing technology, equipped with torque limiters to ensure smooth, safe, and reliable transmission

3. Fully engaged, zero clearance twin-screw mechanism effectively controls shear force to ensure that all materials expand during puffing

The maturation time inside the cavity is consistent with the coefficient of particle expansion

4. The new type of fully wear-resistant alloy screw and bimetallic expansion cavity sleeve effectively reduce wear and ensure that the equipment operates at high temperatures

Long term stable operation under production capacity and high-quality conditions

5. Effectively allocate reasonable shear forces in different areas of the extrusion chamber while ensuring high quality

Effectively increase production

6. The discharge of the raw material device makes the extruded expanded material more aesthetically pleasing, and the output of the small hole diameter mold increases by 30%-

40%. The material shape is uniform and stable

7. The automatic control system simplifies operations and reduces manual labor intensity. Make all data traceable

Record and minimize the impact of operators on the quality of puffed products; Advanced Control Components in Europe

Ensure the stability of the control system

| Model number | Host power | Feeding power | Single axis quenching and tempering power | Dual axis differential modulation power | Production volume |

XYPH95X2 | 160 | 2.2 | 4 | 11 | 2-4 |

| XYPH120X2 | 250 | 2.2 | 5.5 | 18.5 | 5-7 |

| XYPH150X2 | 355 | 2.2 | 5.5 | 18.5 | 8-12 |

XYPH series twin-screw wet water puffing machine

Online Service

Online Service