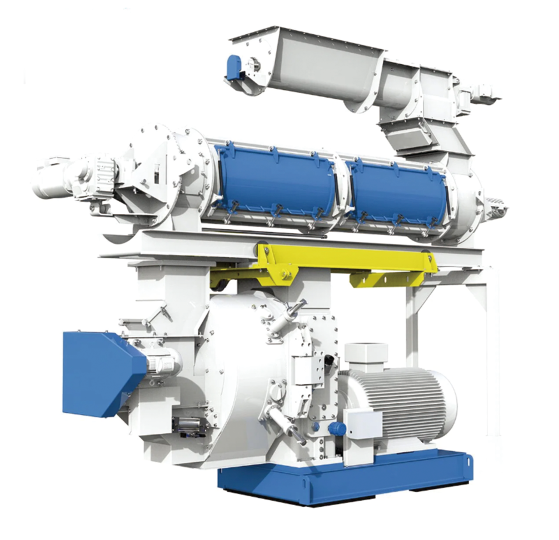

Granulator

granulator

Main features

Technical reference

1. High precision gear direct transmission, high transmission efficiency, and stable operation

2. The bearings and oil seals of the key parts of the main transmission system of high-end models are all imported

3. All stainless steel feeder, variable pitch anti arch structure, with electromagnetic speed control and imported variable frequency speed control available for selection

4. There are livestock and poultry type, aquatic type, enlarged type, single-layer or multi-layer stainless steel conditioner structure, which controls the conditioning and maturation time, and improves the quality of feed. 5. The shaft end of the conditioner is specially sealed and adopts a direct steam inlet method, which ensures more complete contact between the material and steam

6. The selection and assembly clearance of the main bearings are fully guaranteed from the structural design, and the clearance of the main bearings will not be caused by the breakage or replacement of the safety pin

The drift of the main bearings extends their service life, fully ensuring the long-term stable and efficient operation of the equipment

7. The new type of box adopts a special casting process and is processed by an imported machining center with high precision in the hole system

8. The connection between the motor and gearbox adopts a new type of snake shaped spring coupling, which has large compensation and smoother operation

9. The ring mold and transmission wheel adopt a three piece quick release precision casting clamp, making the ring mold easy and fast to disassemble

10. The door cover and inclined groove are made of all stainless steel. Strong anti-corrosion ability and long service life

11. The whole machine adopts a heavy-duty welded base structure, equipped with iron removal and overload protection devices, fully considering the protection of the host during use

| Model number | HHZLH320 | HHZLH350 | HHZLH400 | HHZLH420 | HHZLH508 | HHZLH558 |

| Inner diameter of ring mold | Φ 320 | Φ 350 | Φ 400 | Φ 420 | Φ 508 | Φ 558 |

| Motor power | 37 | 55 | 75/90 | 110 | 132/160 | 160/200 |

| Modulator power | 2.2 | 2.2 | 5.5 | 5.5/7.5 | 11 | 15/18.5 |

| Feeder power | 0.55 | 0.55 | 1.5 | 1.5 | 1.5 | 2.2 |

| Production volume | 2-5 | 3-6 | 5-8 | 8-12 | 12-18 | 18-25 |

| Number of pressure rollers | 2 | 2 | 2 | 2 | 2 | 2 |

在线客服

在线客服